Archives: Equipment

Sub-Bases

Montgomery Sub-Bases provide a common platform for the hog, motor and power transmission. We construct a rigid base using structural steel and build a motor pedestal using heavy plate to keep hog and motor securely aligned. Typical configurations are single motor direct drive, dual motor synchronous drive, or L-shaped to accommodate a V-Belt pulley drive.

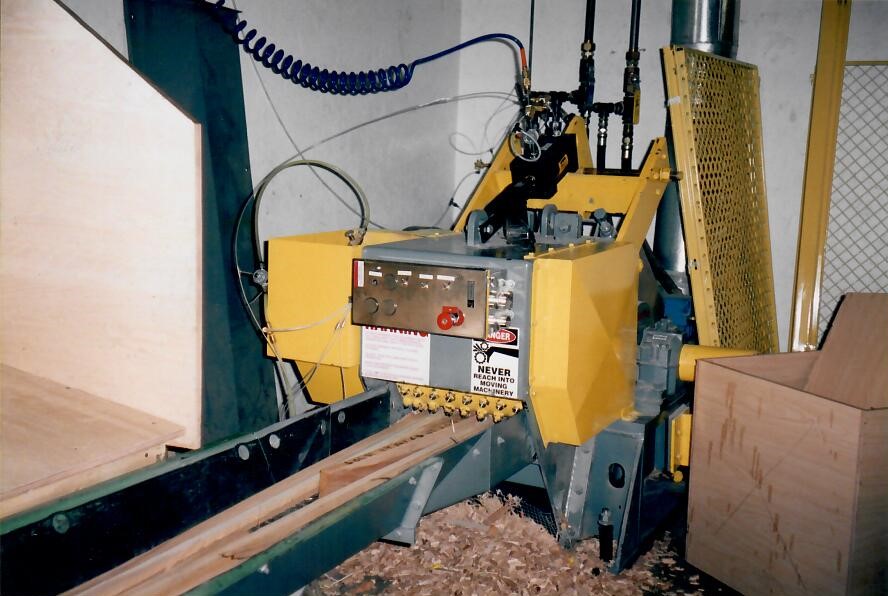

Powered Feed Rolls

The Montgomery Powered Feed Roll is designed to work with our Current Sensing Unit to process slabs in a horizontal feed configuration. They are available for all horizontal infeed hogs–including blo-hogs, horizontal discharge hogs, and rear discharge hogs.

The combination of a Powered Feed Roll and Current Sensing Unit also empowers the hog to successfully feed at a lower RPM, which results in a lower level of operating noise. Adjustable pressure via a counterweight system requires no hydraulics or pneumatics. Straightforward and tough.

Click on the different Powered Feed Roll components on the image to the right to learn more about what makes a Montgomery Powered Feed Roll Unique. Or, browse through examples in the slideshow below.

Powered Feed Roll Components

Blo-Hog Compatibility

Montgomery Powered Feed Rolls are compatible with all horizontal infeed models, even horizontal blo-hogs.

Locking Padeyes for Easy Maintenance

Convenient Locking Padeyes on the Hog housing allow for the Feed Roll to be locked in its maintenance position. This makes it easier to change anvils, replace feed roll spikes, and perform other routine maintenance.

Counterweights for Controlled Feed

Counterweights on the back of the Powered Feed Roll allow the user to control the resistance to feed. The counterweights allow the feed to be throttled or increased depending on the application. Best of all, the counterweight system allows for the Montgomery Powered Feed Roll to function without the hassle of hydraulics or pneumatics.

Feed Height Adjusters

Feed Height Adjusters located on the Hog housing allow the user to adjust the height of the Powered Feed Roll. The Feed Roll can be raised or lowered to let in different heights of scrap, depending on the application.

Rotating Drum for Optimal Infeed

A rotating drum with spikes allows for infeed material to be gripped and pulled into the Hog cutting chamber.

Guard Covers

Guard Covers over both Feed Roll arms help to keep dust at bay. They also help protect the Powered Feed Roll motor and gear reducer from the elements.

Flange Bearings

Flange bearings allow for minimal resistance between the Feed Roll pivot shafts and the hog housing, keeping everything running smoothly.

Hydraulics

When it’s time to pull maintenance, we make it easy with labor saving hydraulics. We offer hydraulic door openers, rotor brakes and screen reset mechanisms.

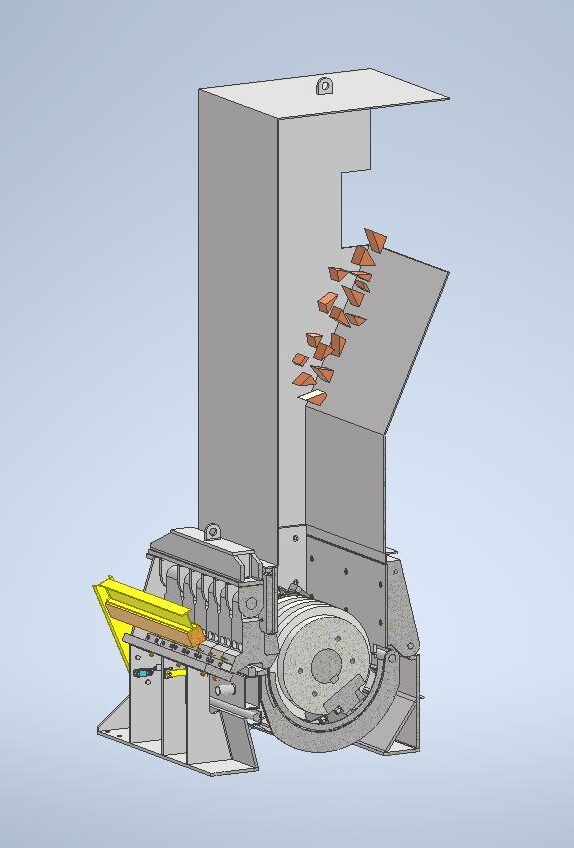

Feed Hoppers

The Feed Hopper should be a simple means to an end. Straightforward in concept but the wrong geometry can create big headaches. Montgomery Hoppers are thoughtfully designed for both machine and material geometry. When material is fed properly, the abilities of the machine are unleashed.

All gravity-fed models require a Feed Hopper for the safe feeding of material into the hog.

Click on the different Feed Hopper components on the image to the right to learn more about what makes a Montgomery Industries Feed Hopper unique. Or, browse through examples in the slideshow below.

Feed Hopper Components

Hog

A 39 CS-KC Hog with a 30″ Feed Opening is shown for reference. The hopper gets welded onto the hog’s companion flange that then bolts down to the rest of the hog housing.

If you made your own hopper but are finding it doesn’t quite work, not to worry – hogs can easily be retrofitted to include a Montgomery Industries feed hopper.

Infeed Material

The hopper is designed to direct infeed material into the rotor downstroke. This helps prevent kickback and lessens recirculation.

Feed Hopper

The Montgomery Industries Feed Hopper has been carefully engineered with the right geometry for proper feeding of your hog.

Our feed hoppers ensure that material gets directed into the rotor downstroke – not into the walls or ceiling of the hopper.

Drive Packages

The proper operation of our equipment requires the proper transmission of power. Montgomery is experienced in providing robust drive packages that can keep up with our rugged machines. We offer motors, direct drive couplings and V-Belt drive systems to transform your power source into commanding rotational energy.

Current Sensing Units

When scrap comes off the line in fits and starts, Current Sensing Units can optimize hogging by providing a steady stream of material. Available for all Montgomery Horizontal Feed Hogs, they can be interlocked with Vibrating Conveyors, Powered Feed Rolls, and other discharge equipment.

The Current Sensing Unit is a control device that automatically meters the amperage load of the Hog motor. When the motor reaches a field-adjusted threshold, the Current Sensing Unit throttles the infeed equipment to avoid over-feeding. Additionally, when the Hog motor amperage falls back below its preset level, the Current Sensing Unit automatically restarts any connected infeed and discharge equipment.

Column Legs

Once our Sub-Base creates a rigid common platform, our Column Legs elevate the equipment with sound, structural support. We use heavy structural beam, steel gussets in both planes, 1/2” thick steel plates at the Sub-Base interface and 1” thick foot plates to distribute the load.

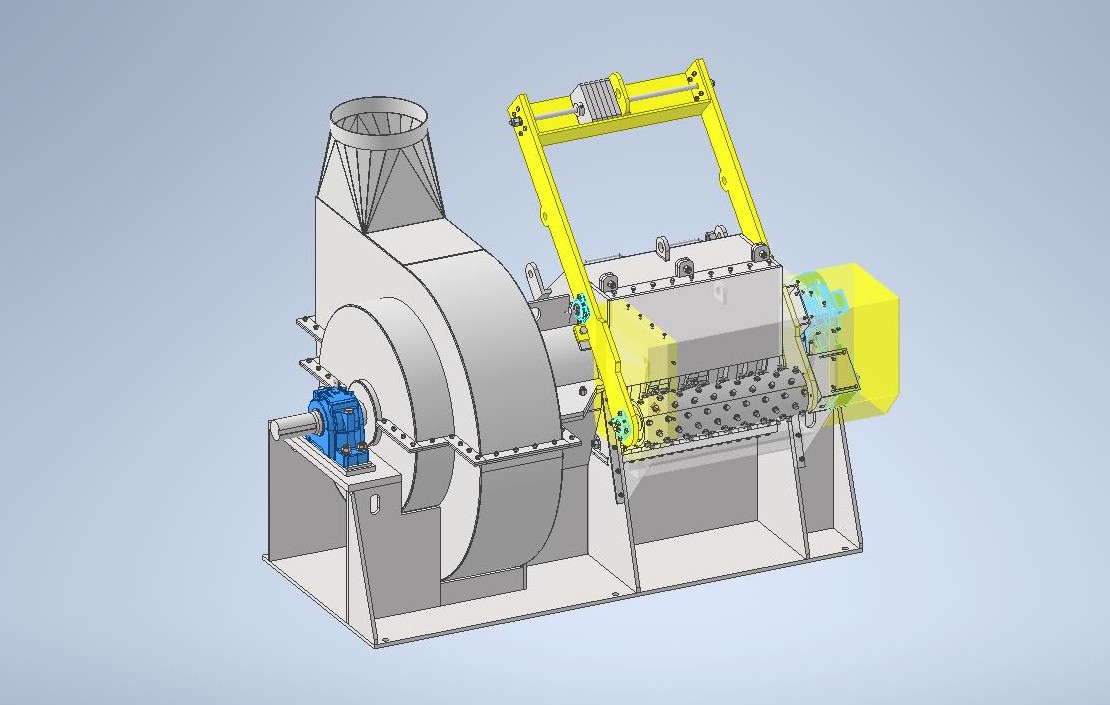

Severe Duty Fan

Severe Duty fans are recommended on applications where substantial wear on the fan is anticipated. A diamond pattern of hardsurfacing is applied to the fan blades and wear liners are added to the housing.

Capacities:

500 CFM to 50,000 CFM

Heavy Duty Fan

General purpose centrifugal blower used to convey material such as bark, chips, hoggings, paper, sawdust, shavings and veneer waste. Parts are welded for maximum strength. Fan base is bolted to the fan housing, providing many discharge positions.

Air Flow Capacities:

500 CFM to 50,000 CFM

HH36

Typical applications include bark and the coarse reduction of solids such as yard trash or construction debris.

HH36 rings with individually pinned hammers provide a 36” cutting circle.

Rotor assembly incorporates two 3” X 23” steel flywheels for rotational momentum and to prevent material from binding against housing end plates.

Gravity discharge of material out of an opening in the base plate of the hog.

XL-KC

Typical applications include bark and wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 11” thick, as well as logs, lily pads, broken pallets and 60” whole pallets.

XL-KC removable lug rings have a 36” cutting circle. The rotor has an inherently large rotational energy, so no flywheel is needed to process through momentary surge loads.

The rings can be hardsurfaced to extend their economic life in abrasive applications.

Gravity discharge of material out of an opening in the base plate of the hog.

CS-KC

Typical applications include bark and wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 9” thick, as well as logs, lily pads, broken pallets and 60” whole pallets.

CS-KC removable lug rings have a 32” cutting circle. The rotor has an inherently large rotational energy, so no flywheel is needed to process through momentary surge loads.

The rings can be hardsurfaced to extend their economic life in abrasive applications.

Gravity discharge of material out of an opening in the base plate of the hog.

PM-KC

Typical applications include bark and wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 6” thick, as well as lily pads, broken pallets and 60” whole pallets. It can also be configured with special thin plate screens to process polyurethane and polymers.

PM-KC fixed lug rings have a 22” cutting circle and the rotor incorporates a 6” X 36” steel flywheel to process through momentary surge loads. The rings can be hardsurfaced to extend their economic life in abrasive applications.

Gravity discharge of material out of an opening in the base plate of the hog.

PM-HZF-BH

Typical applications include wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 5” thick. Other applications include veneer roundup, plywood, and particleboard.

The PM series uses PM-GM rings with a 22” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

The discharge material can typically be conveyed up to 100 feet into a cyclone, truck, or open field using the #40, #50 or #60 Integral Fan.

PM-HZF, Rear Discharge

Typical applications include wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 5” thick.

Other applications include veneer roundup, plywood, and particleboard.

The PM series uses PM-GM rings with a 22” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

PM-HZF, Bottom Discharge

Typical applications include wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 5” thick.

Other applications include veneer roundup, plywood, and particleboard.

The PM series uses PM-GM rings with a 22” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

Gravity discharge of material out of an opening in the base plate of the hog.

PM-BH

Typical applications include bark and wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 5” thick.

Other applications include veneer roundup, polyurethane scrap, plywood, paper, gypsum, particleboard, broken and whole pallets.

The PM series uses PM-GM rings with a 22” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The rings and fanwheel can be hardsurfaced to extend their economic life in abrasive applications.

The discharge material can typically be conveyed up to 100 feet into a cyclone, truck, or open field using the #40, #50 or #60 Integral Fan.

PM-ER

Typical applications include bark and wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 5” thick.

Other applications include veneer roundup, polyurethane scrap, plywood, paper, gypsum, particleboard, broken and whole pallets.

The PM series uses PM-GM rings with a 22” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The rings can be hardsurfaced to extend their economic life in abrasive applications.

Gravity discharge of material out of an opening in the base plate of the hog.

BS-RC

Typical applications include bull screen rejects processing through a ½” or ¾” rectangular holed screen.

When the secondary grinding involves bull screen rejects in the harsh papermaking environment, the Montgomery Bull Screen Rechipper comes prepared for the job.

In addition to the aggressive cut and wear liners in the cutting chamber, the bearings are sealed, hose bibs are provided for flushing, stainless steel is welded to the rings and the housing is covered in a special anti-corrosion epoxy.

For the ultimate in corrosion resistance, the housing, wear liners, hardware, rings, teeth and screen can all be manufactured out of stainless steel.

HD-RC-BH

Typical applications include chips and shavings.

The rechipper is a modified HD hog with a more aggressive cut, hardsurfaced ring lugs and abrasion resistant wear lines in the cutting chamber.

The HD series uses HD-GM rings with an 18-3/4” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The discharge material can typically be conveyed up to 100 feet into a cyclone, truck, or open field using the #40, #50 or #60 Integral Fan.

HD-RC

Typical applications include chips and shavings.

The rechipper is a modified HD hog with a more aggressive cut, hardsurfaced ring lugs and abrasion resistant wear lines in the cutting chamber.

The HD series uses HD-GM rings with an 18-3/4” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

Gravity discharge of material out of an opening in the base plate of the hog.

HD-HZF-BH

Typical applications include wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 3” thick. Other applications include veneer roundup, plywood, and particleboard.

The HD series uses HD-GM rings with an 18-3/4” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

The discharge material can typically be conveyed up to 100 feet into a cyclone, truck, or open field using the #40 or #50 Integral Fan.

HD-HZF, Rear Discharge

Typical applications include wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 3” thick. Other applications include veneer roundup, plywood, and particleboard.

The HD series uses HD-GM rings with an 18-3/4” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

HD-HZF, Bottom Discharge

Typical applications include wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 3” thick.

Other applications include veneer roundup, plywood, and particleboard.

The HD series uses HD-GM rings with an 18-3/4” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

Gravity discharge of material out of an opening in the base plate of the hog.

HD-BH

Typical applications include bark and wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 3” thick.

Other applications include veneer roundup, polyurethane scrap, plywood, paper, gypsum and particleboard.

The HD series uses HD-GM rings with an 18-3/4” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The rings and fanwheel can be hardsurfaced to extend their economic life in abrasive applications.

The discharge material can typically be conveyed up to 100 feet into a cyclone, truck, or open field using the #40, #50 or #60 Integral Fan.

HD-ER

Typical applications include bark and wood scrap such as blocks, cutoffs, edgings, slabs and trim ends up to 4” thick.

Other applications include veneer roundup, polyurethane scrap, plywood, paper, gypsum and particleboard.

The HD series uses HD-GM rings with an 18-3/4” cutting circle and a steel flywheel for stored rotational energy to power through momentary surge loads.

The rings can be hardsurfaced to extend their economic life in abrasive applications.

Gravity discharge of material out of an opening in the base plate of the hog.

FS-HZF-BH

Typical applications include light wood scrap such as thin edgings, rippings and trim ends up to 1” thick with an occasional 2X4.

The FS series incorporates the punch and die design, internal shear pin protection and rugged construction of a Montgomery Hog.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

The discharge material can typically be conveyed up to 100 feet into a cyclone, truck, or open field using the #30 Integral Fan.

FS-HZF, Rear Discharge

Typical applications include light wood scrap such as thin edgings, rippings and trim ends up to 1” thick with an occasional 2X4.

The FS series incorporates the punch and die design, internal shear pin protection and rugged construction of a Montgomery Hog.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

FS-HZF, Bottom Discharge

Typical applications include light wood scrap such as thin edgings, rippings and trim ends up to 1” thick with an occasional 2X4.

The FS series incorporates the punch and die design, internal shear pin protection and rugged construction of a Montgomery Hog.

The horizontal feed is designed for the processing of long pieces using a vibrating conveyor.

Pieces larger than the hog can process in 5 to 10 seconds can be metered with an available Current Sensing Unit.

Gravity discharge of material out of an opening in the base plate of the hog.