Applications

Industry and Material Specializations

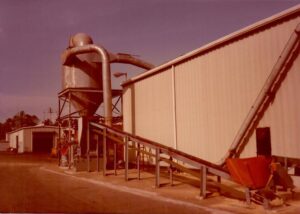

Size reduction provides a means of utilizing many types of dry solids which can be reclaimed, recycled, burned as fuel, or used to generate mulch. Hogs are used to devour waste materials – especially wood waste from sawmills, dimension mills, plywood plants, and other woodworking operations.

Hogs are also used to grind bark removed from raw logs in sawmills and pulp mills, most of which is burned for fuel.

Other applications include pallets, whole logs, veneer scrap, engineered wood products, automobile tires, light aluminium, thin plastics, and polymers.

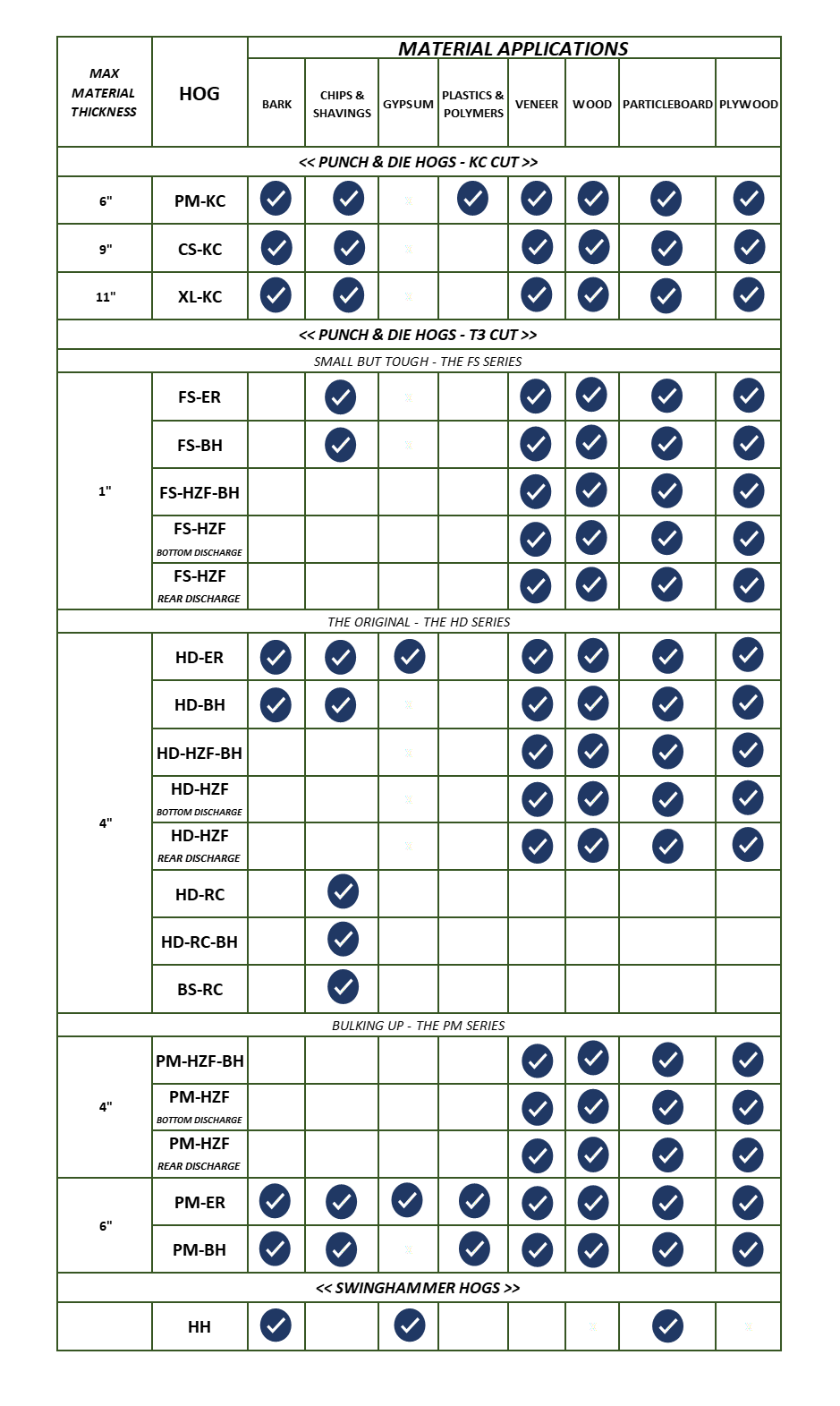

Use the interactive table below to learn more about which materials each hog specializes in processing. Click on the hog names to go to each machine’s product page, or click on the check marks to bring up more information about how each hog handles different materials.

Material Applications

Click on the icons to learn more about each hog and their different applications.

PM-KC - Bark

The punch-and-die system of the PM-KC provides an energy efficient means of processing large volumes of bark, including stringy bark such as Hickory, Cypress, and Basswood.

With robust construction and tramp metal protection, the PM-KC has been designed to handle the toughest of sawmill environments.

The PM-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

It has a common bark processing capacity range of 25-45 tons per hour.

PM-KC - Chips & Shavings

For regrind applications, the PM-KC offers an energy efficient way to process large volumes of material.

It has an average processing capacity of chips and shavings of 14 tons per hour.

All KC models feature an overlapping cut configuration, which is optimal for grinding stringy material like chips or shavings.

The PM-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

PM-KC - Plastics & Polymers

The PM-KC's punch-and-die system provides a unique ability to process light plastics, polybutadiene blocks, polyurethane scrap, and other polymers for recycling into source product for industrial applications.

It can also be configured with special thin plate screens to better process oil shale and plastics.

The PM-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The 15 PM-KC pictured grinds polymer blocks for mixture into asphalt compounds.

PM-KC - Veneer

While almost an insurmountable challenge for traditional hammer hogs and grinders, the Montgomery punch-and-die system is ideally suited to process thin and stringy veneer scrap.

All KC models feature an overlapping cut configuration, which allows for successful processing of soft, spongy, or stringy materials.

The PM-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

On average, the PM-KC can process veneer at a rate of up to 17 tons per hour.

PM-KC - Wood

The PM-KC effectively processes wood blocks, slabs, logs up to 85 pounds, broken pallets, and 60" whole pallets. From green log cuts to kiln dried trims, it provides an effective way to recycle many forms of wood into premium quality wood fiber or landscaping mulch.

The PM-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

It has an average wood processing capacity of up to 20 tons per hour.

The pictured 51 PM-KC grinds wood blocks for boiler fuel.

PM-KC - Particleboard

Easier to grind than wood, particleboard is no match for the power of the KC Series. Especially when a mix of scraps is being thrown in, the PM-KC ensures that all material can be processed.

Though it may be overkill for light-duty applications, the PM-KC provides a rugged solution that can process particleboard as well as tougher wood blocks or stray metal scrap.

The PM-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The PM-KC has an average particleboard processing capacity of up to 36 tons per hour.

PM-KC - Plywood

The ruggedly built KC Series makes quick work of easily processed materials such as plywood. Even when nails, small bolts, or steel strapping are mixed in, the PM-KC is able to process with ease.

Though the PM-KC is overbuilt for light-duty plywood processing applications, it provides the flexibility of also being able to handle heavier duty materials.

The PM-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The PM-KC has an average plywood processing capacity of up to 35 tons per hour.

The 63 PM-KC pictured processes plywood and pallet scrap.

CS-KC - Bark

The punch-and-die system of the CS-KC provides an energy efficient means of processing large volumes of bark, including stringy bark such as Hickory, Cypress, and Basswood.

With robust construction and tramp metal protection, the CS-KC has been designed to handle the toughest of sawmill environments.

The CS-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

It has a common bark processing capacity range of 30-65 tons per hour.

The pictured 51 CS-KC processes bark for mulch.

CS-KC - Chips & Shavings

For regrind applications, the CS-KC offers an energy efficient way to process large volumes of material.

It has an average processing capacity of chips and shavings of 26 tons per hour.

All KC models feature an overlapping cut configuration, which is optimal for grinding stringy material like chips or shavings.

The CS-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The pictured 75 CS-KC processes chip screen rejects for boiler fuel.

CS-KC - Veneer

While almost an insurmountable challenge for traditional hammer hogs and grinders, the Montgomery punch-and-die system is ideally suited to process thin and stringy veneer scrap.

All KC models feature an overlapping cut configuration, which allows for successful processing of soft, spongy, or stringy materials.

The CS-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

On average, the CS-KC can process veneer at a rate of up to 25 tons per hour.

CS-KC - Wood

The CS-KC effectively processes wood blocks, slabs, logs up to 125 pounds, broken pallets, and 60" whole pallets. From green log cuts to kiln dried trims, it provides an effective way to recycle many forms of wood into premium quality wood fiber or landscaping mulch.

The CS-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

It has an average wood processing capacity of up to 29 tons per hour.

CS-KC - Particleboard

Easier to grind than wood, particleboard is no match for the power of the KC Series. Especially when a mix of scraps is being thrown in, the CS-KC ensures that all material can be processed.

Though it may be overkill for light-duty applications, the CS-KC provides a rugged solution that can process particleboard as well as tougher wood blocks or stray metal scrap.

The CS-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The CS-KC has an average particleboard processing capacity of up to 53 tons per hour.

CS-KC - Plywood

The ruggedly built KC Series makes quick work of easily processed materials such as plywood. Even when nails, small bolts, or steel strapping are mixed in, the CS-KC is able to process with ease.

Though the CS-KC is overbuilt for light-duty plywood processing applications, it provides the flexibility of also being able to handle heavier duty materials.

The CS-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The CS-KC has an average plywood processing capacity of up to 51 tons per hour.

XL-KC - Bark

The punch-and-die system of the XL-KC provides an energy efficient means of processing large volumes of bark, including stringy bark such as Hickory, Cypress, and Basswood.

With robust construction and tramp metal protection, the XL-KC has been designed to handle the toughest of sawmill environments.

The XL-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

It has a common bark processing capacity range of 45-90 tons per hour.

XL-KC - Chips & Shavings

For regrind applications, the XL-KC offers an energy efficient way to process large volumes of material.

It has an average processing capacity of chips and shavings of 29 tons per hour.

All KC models feature an overlapping cut configuration, which is optimal for grinding stringy material like chips or shavings.

The XL-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

XL-KC - Veneer

While almost an insurmountable challenge for traditional hammer hogs and grinders, the Montgomery punch-and-die system is ideally suited to process thin and stringy veneer scrap.

All KC models feature an overlapping cut configuration, which allows for successful processing of soft, spongy, or stringy materials.

The XL-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

On average, the XL-KC can process veneer at a rate of up to 34 tons per hour.

XL-KC - Wood

The XL-KC effectively processes wood blocks, slabs, logs up to 165 pounds, broken pallets, and 60" whole pallets. From green log cuts to kiln dried trims, it provides an effective way to recycle many forms of wood into premium quality wood fiber or landscaping mulch.

The XL-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

It has an average wood processing capacity of up to 40 tons per hour.

XL-KC - Particleboard

Easier to grind than wood, particleboard is no match for the power of the KC Series. Especially when a mix of scraps is being thrown in, the XL-KC ensures that all material can be processed.

Though it may be overkill for light-duty applications, the XL-KC provides a rugged solution that can process particleboard as well as tougher wood blocks or stray metal scrap.

The XL-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The XL-KC has an average particleboard processing capacity of up to 59 tons per hour.

XL-KC - Plywood

The ruggedly built KC Series makes quick work of easily processed materials such as plywood. Even when nails, small bolts, or steel strapping are mixed in, the XL-KC is able to process with ease.

Though the XL-KC is overbuilt for light-duty plywood processing applications, it provides the flexibility of also being able to handle heavier duty materials.

The XL-KC utilizes gravity infeed of material through a hole in the top of the machine. Material is discharged through an opening in the base plate.

The XL-KC has an average plywood processing capacity of up to 69 tons per hour.

FS-ER - Chips & Shavings

The overlapping cut option available for all Montgomery punch-and-die models allows for the grinding of stringy materials such as chips or shavings.

For light-duty applications, the FS-ER provides an energy efficient and cost-effective solution to the processing of large volumes of material.

For the FS-ER, material is fed in through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

On average, the FS-ER can process chips and shavings at a rate of up to 4 tons per hour.

FS-ER - Veneer

The Montgomery punch-and-die system allows the FS-ER to process thin and stringy veneer scrap. It excels in light-duty shredding applications, and can accept scrap up to 1" thick.

For the FS-ER, material is fed in through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The FS-ER has an average veneer processing capacity of up to 3 tons per hour.

FS-ER - Wood

The FS-ER excels in light-duty wood shredding applications and is able to process all species of hardwood and softwood--green or dry.

It is able to process thin edgings and trim-ends up to 1" thick, and will accept an occasional 2x4.

For the FS-ER, material is fed in through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The FS-ER has an average wood processing capacity of up to 4 tons per hour.

FS-ER - Particleboard

Since particleboard is relatively easy to break down, the FS-ER provides a cost-effective solution to processing scrap. Ideal for light-duty applications, it can handle particleboard up to 1" thick.

The FS-ER is perfectly suited for grinding of small scrap, and doesn't need the same power requirements as some of the heavier-duty models.

For the FS-ER, material is fed in through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The FS-ER has an average particleboard processing capacity of up to 9 tons per hour.

FS-ER - Plywood

The FS-ER provides a cost-effective solution to breaking down materials like plywood. Requiring less space and less power than some of the bulkier machines, it still is able to pull its own weight when it comes to processing of smaller materials.

Able to accept scrap up to 1" thick, the FS-ER is ideally suited for light-duty plywood processing applications.

For the FS-ER, material is fed in through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The FS-ER has an average plywood processing capacity of up to 7 tons per hour.

FS-BH - Chips & Shavings

The overlapping cut option available for all Montgomery punch-and-die models allows for the grinding of stringy materials such as chips or shavings.

For light-duty applications, the FS-BH provides an energy efficient and cost-effective solution to the processing of large volumes of material.

Material is fed into the FS-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-BH - Veneer

The Montgomery punch-and-die system allows the FS-BH to process thin and stringy veneer scrap. It excels in light-duty shredding applications, and can accept scrap up to 1" thick.

Material is fed into the FS-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-BH - Wood

The FS-BH excels in light-duty wood shredding applications and is able to process all species of hardwood and softwood--green or dry.

It is able to process thin edgings and trim-ends up to 1" thick, and will accept an occasional 2x4.

Material is fed into the FS-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-BH - Particleboard

Since particleboard is relatively easy to break down, the FS-BH provides a cost-effective solution to processing scrap. Ideal for light-duty applications, it can handle particleboard up to 1" thick.

The FS-BH is perfectly suited for grinding of small scrap, and doesn't need the same power requirements as some of the heavier-duty models.

Material is fed into the FS-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-BH - Plywood

The FS-BH provides a cost-effective solution to breaking down materials like plywood. Requiring less space and less power than some of the bulkier machines, it still is able to pull its own weight when it comes to processing of smaller materials.

Able to accept scrap up to 1" thick, the FS-BH is ideally suited for light-duty plywood processing applications.

Material is fed into the FS-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-HZF-BH - Veneer

The FS-HZF-BH is ideally suited to the light-duty processing of veneer. It can accept scrap up to 1" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal feed allows for more efficient grinding of long pieces of veneer, and the Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-HZF-BH - Wood

The FS-HZF-BH is ideal for processing light wood scrap and thin edgings up to 1" thick, as well as the occasional 2x4.

The horizontal feed allows for more efficient grinding of long pieces of wood, and the Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

The 18FS30-HZF pictured operates at a furniture manufacturing plant grinding cutoffs and trim ends.

FS-HZF-BH - Particleboard

When particleboard scrap is relatively thin and long, the FS-HZF-BH shines. It can accept material up to 1" thick and over 8' long.

A light-weight option, the FS-HZF-BH eats particleboard with ease. It also cuts down on costs, requiring less power than some of the heavy-duty models.

The FS-HZF-BH is an energy efficient and cost-effective solution to light-duty particleboard grinding applications.

An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-HZF-BH - Plywood

The FS-HZF-BH is aptly suited to the processing of light-duty materials like plywood. It is ideal for applications where plywood scraps are relatively thin and long, and is able to grind scrap up to 1" thick and over 8' long.

Requiring less power than the heavy-duty options, the FS-HZF-BH is a cost-effective, energy efficient option when it comes to processing of plywood scrap.

An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

FS-HZF-BD - Veneer

The FS-HZF-BD is ideally suited to the light-duty processing of veneer. It can accept scrap up to 1" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal infeed allows for more efficient grinding of long pieces of veneer. Material is discharged via gravity through an opening in the base plate of the hog.

FS-HZF-BD - Wood

The FS-HZF-BD is ideal for processing light wood scrap and thin edgings up to 1" thick, as well as the occasional 2x4.

The horizontal infeed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long. Material is discharged via gravity through an opening in the base plate of the hog.

FS-HZF-BD - Particleboard

When particleboard scrap is relatively thin and long, the FS-HZF-BD shines. It can accept material up to 1" thick and over 8' long.

A light-weight option, the FS-HZF-BD eats particleboard with ease. It also cuts down on costs, requiring less power than some of the heavy-duty models.

The FS-HZF-BD is an energy efficient and cost-effective solution to light-duty particleboard grinding applications.

Material is discharged via gravity through an opening in the base plate of the hog.

FS-HZF-BD - Plywood

The FS-HZF-BD is aptly suited to the processing of light-duty materials like plywood. It is ideal for applications where plywood scraps are relatively thin and long, and is able to grind scrap up to 1" thick and over 8' long.

Requiring less power than the heavy-duty options, the FS-HZF-BD is a cost-effective, energy efficient option when it comes to processing of plywood scrap.

Material is discharged via gravity through an opening in the base plate of the hog.

FS-HZF-RD - Veneer

The FS-HZF-RD is ideally suited to the light-duty processing of veneer. It can accept scrap up to 1" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal infeed allows for more efficient grinding of long pieces of veneer. Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

FS-HZF-RD - Wood

The FS-HZF-RD is ideal for processing light wood scrap and thin edgings up to 1" thick, as well as the occasional 2x4.

The horizontal infeed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

The pictured 18 FS-HZF RD operates at a cabinet manufacturing company processing hardwood edgings.

FS-HZF-RD - Particleboard

When particleboard scrap is relatively thin and long, the FS-HZF-RD shines. It can accept material up to 1" thick and over 8' long.

A light-weight option, the FS-HZF-RD eats particleboard with ease. It also cuts down on costs, requiring less power than some of the heavy-duty models.

The FS-HZF-RD is an energy efficient and cost-effective solution to light-duty particleboard grinding applications.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

FS-HZF-RD - Plywood

The FS-HZF-RD is aptly suited to the processing of light-duty materials like plywood. It is ideal for applications where plywood scraps are relatively thin and long, and is able to grind scrap up to 1" thick and over 8' long.

Requiring less power than the heavy-duty options, the FS-HZF-RD is a cost-effective, energy efficient option when it comes to processing of plywood scrap.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

HD-ER - Bark

The punch-and-die system of the HD-ER provides an effective means of processing large volumes of bark. It is available with an overlapping cut option that makes it especially suited for stringy bark such as Hickory, Cypress, and Basswood.

Even when chunks of bark may be mixed in with a variety of other scrap, the HD-ER is able to retain its aggressive processing abilities. It can handle scrap up to 4" thick.

Material is fed into the HD-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The HD-ER has an average bark processing capacity of up to 24 tons per hour.

HD-ER - Chips & Shavings

The overlapping cut option available for all Montgomery punch-and-die models allows for the grinding of stringy materials such as chips or shavings. This allows the HD-ER to process light materials with ease.

In the case that chips or shavings are mixed in with larger debris, the HD-ER still maintains its aggressive processing capabilities. It can handle scrap up to 4" thick.

Material is fed into the HD-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The HD-ER has an average chips and shavings processing capacity of up to 11 tons per hour.

HD-ER - Gypsum

The HD-ER provides infeed opening options large enough to accommodate sheets of gypsum board.

Able to grind much stronger materials, the HD-ER can process gypsum with ease. It provides a cost-effective way to grind gypsum, while still maintaining an aggressive cut.

Material is fed into the HD-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The HD-ER has an average gypsum processing capacity of up to 18 tons per hour.

HD-ER - Veneer

When it comes to medium-duty processing applications, the HD-ER shines. Especially in the case of thin materials like veneer, the HD-ER maintains a big appetite for waste material. It can accept scrap pieces up to 4" thick.

The overlapping cut option available on all Montgomery punch-and-die hogs makes grinding of stringy, spongy, or soft materials like veneer a breeze.

Material is fed into the HD-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The HD-ER has an average veneer processing capacity of up to 9 tons per hour.

HD-ER - Wood

The HD-ER is aptly suited for the grinding of wood blocks, edgings, cutoffs, slabs, and trim ends up to 4" thick. In the case other debris gets mixed in with the wood, its rugged construction also allows it to handle occasional light tramp steel and small nails.

The pictured 34 HD-ER processes wood scrap from pallet manufacturing.

Material is fed into the HD-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

It has an average wood processing capacity of up to 10 tons per hour.

HD-ER - Particleboard

Since particleboard is relatively easy to break down, the HD-ER provides a cost-effective solution to processing scrap. Ideal for medium-duty applications, it can handle particleboard up to 4" thick.

Material is fed into the HD-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The HD-ER has an average particleboard processing capacity of up to 23 tons per hour.

HD-ER - Plywood

The HD-ER provides a cost-effective solution to medium-duty processing of plywood scrap. Bringing more power to the table than the FS-ER, it is able to accept plywood scrap up to 4" thick.

The HD-ER has the benefit of being able to grind a wide mix of materials--great for when different types of scrap are all thrown in at once. If light tramp metal or small nails get mixed in, the HD-ER can handle them too.

Material is fed into the HD-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The HD-ER has an average plywood processing capacity of up to 18 tons per hour.

HD-BH - Bark

The punch-and-die system of the HD-BH provides an effective means of processing large volumes of bark. It is available with an overlapping cut option that makes it especially suited for stringy bark such as Hickory, Cypress, and Basswood.

Even when chunks of bark may be mixed in with a variety of other scrap, the HD-BH is able to retain its aggressive processing abilities. It can handle scrap up to 4" thick.

Material is fed into the HD-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-BH - Chips & Shavings

The overlapping cut option available for all Montgomery punch-and-die models allows for the grinding of stringy materials such as chips or shavings. This allows the HD-BH to process light materials with ease.

In the case that chips or shavings are mixed in with larger debris, the HD-BH still maintains its aggressive processing capabilities. It can handle scrap up to 4" thick.

Material is fed into the HD-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-BH - Veneer

When it comes to medium-duty processing applications, the HD-BH shines. Especially in the case of thin materials like veneer, the HD-BH maintains a big appetite for waste material. It can accept scrap pieces up to 4" thick.

The overlapping cut option available on all Montgomery punch-and-die hogs makes grinding of stringy, spongy, or soft materials like veneer a breeze.

Material is fed into the HD-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-BH - Wood

The HD-BH is aptly suited for the grinding of wood blocks, edgings, cutoffs, slabs, and trim ends up to 4" thick. In the case other debris gets mixed in with the wood, its rugged construction also allows it to handle occasional light tramp steel and small nails.

Material is fed into the HD-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-BH - Particleboard

Since particleboard is relatively easy to break down, the HD-BH provides a cost-effective solution to processing scrap. Ideal for medium-duty applications, it can handle particleboard up to 4" thick.

Material is fed into the HD-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-BH - Plywood

The HD-BH provides a cost-effective solution to medium-duty processing of plywood scrap. Bringing more power to the table than the FS-BH, it is able to accept plywood scrap up to 4" thick.

The HD-BH has the benefit of being able to grind a wide mix of materials--great for when different types of scrap are all thrown in at once. If light tramp metal or small nails get mixed in, the HD-BH can handle them too.

Material is fed into the HD-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-HZF-BH - Veneer

The HD-HZF-BH is ideally suited to the medium-duty processing of veneer. It can accept scrap up to 4" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal feed allows for more efficient grinding of long pieces of veneer, and the Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-HZF-BH - Wood

The HD-HZF-BH is aptly suited for the grinding of wood blocks, edgings, cutoffs, slabs, and trim ends up to 4" thick. In the case other debris gets mixed in with the wood, its rugged construction also allows it to handle occasional light tramp steel and small nails.

The horizontal infeed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long.

An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

The 26HD40-HZF pictured processes trim blocks & cutoffs.

HD-HZF-BH - Particleboard

The horizontal infeed of the HD-HZF-BH allows it to accept pieces of particleboard scrap up to 4" thick and over 8' long. This makes it ideal for medium-duty grinding applications.

Since particleboard is relatively easy to break down, the HD-HZF-BH is able to process large volumes of scrap with ease.

An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-HZF-BH - Plywood

The horizontal infeed of the HD-HZF-BH allows it to accept long pieces of plywood scrap. Bringing more power to the table than its FS Series counterpart, it can handle plywood up to 4" thick and over 8' long.

The HD-HZF-BH has the added benefit of being able to grind a wide mix of materials. If light tramp metal or small nails get mixed in, the HD-HZF-BH can process them with ease.

An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HD-HZF-BD - Veneer

The HD-HZF-BD is ideally suited to the light-duty processing of veneer. It can accept scrap up to 4" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal infeed allows for more efficient grinding of long pieces of veneer. Material is discharged via gravity through an opening in the base plate of the hog.

HD-HZF-BD - Wood

The HD-HZF-BD is aptly suited for the grinding of wood blocks, edgings, cutoffs, slabs, and trim ends up to 4" thick. In the case other debris gets mixed in with the wood, its rugged construction also allows it to handle occasional light tramp steel and small nails.

The horizontal infeed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long.

Material is discharged via gravity through an opening in the base plate of the hog.

The 10 HD-HZF BD pictured is used at a sawmill to process hardwood slabs, cutoffs, & edgings.

HD-HZF-BD - Particleboard

The horizontal infeed of the HD-HZF-BD allows it to accept pieces of particleboard scrap up to 4" thick and over 8' long. This makes it ideal for medium-duty grinding applications.

Since particleboard is relatively easy to break down, the HD-HZF-BD is able to process large volumes of scrap with ease.

Material is discharged via gravity through an opening in the base plate of the hog.

The pictured 18 HD-HZF BD processes particleboard scraps with veneer finish.

HD-HZF-BD - Plywood

The horizontal infeed of the HD-HZF-BD allows it to accept long pieces of plywood scrap. Bringing more power to the table than its FS Series counterpart, it can handle plywood up to 4" thick and over 8' long.

The HD-HZF-BD has the added benefit of being able to grind a wide mix of materials. If light tramp metal or small nails get mixed in, the HD-HZF-BD can process them with ease.

Material is discharged via gravity through an opening in the base plate of the hog.

HD-HZF-RD - Veneer

The HD-HZF-RD is ideally suited to the light-duty processing of veneer. It can accept scrap up to 4" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal infeed allows for more efficient grinding of long pieces of veneer. Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

HD-HZF-RD - Wood

The HD-HZF-RD is aptly suited for the grinding of wood blocks, edgings, cutoffs, slabs, and trim ends up to 4" thick. In the case other debris gets mixed in with the wood, its rugged construction also allows it to handle occasional light tramp steel and small nails.

The horizontal infeed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

The 42 HD-HZF RD pictured is used to process pine scrap.

HD-HZF-RD - Particleboard

The horizontal infeed of the HD-HZF-RD allows it to accept pieces of particleboard scrap up to 4" thick and over 8' long. This makes it ideal for medium-duty grinding applications.

Since particleboard is relatively easy to break down, the HD-HZF-RD is able to process large volumes of scrap with ease.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

The 18 HD-HZF RD pictured is used at a furniture manufacturing plant to grind particleboard scrap and trim for use as boiler fuel.

HD-HZF-RD - Plywood

The horizontal infeed of the HD-HZF-RD allows it to accept long pieces of plywood scrap. Bringing more power to the table than its FS Series counterpart, it can handle plywood up to 4" thick and over 8' long.

The HD-HZF-RD has the added benefit of being able to grind a wide mix of materials. If light tramp metal or small nails get mixed in, the HD-HZF-RD can process them with ease.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

HD-RC - Chips & Shavings

The HD-RC is a modified HD hog with a more aggressive cut, hardsurfaced ring lugs, and abrasion resistant wear lines in the cutting chamber. This makes it ideally suited for secondary grinding of chips and shavings.

It is typically used for processing chipscreen rejects in pulp mills. Utilizing the Montgomery punch-and-die system, the HD-RC eliminates re-screening and produces a low percentage of pulp fines.

The HD-RC differs from the HD-RC-BH in that material is discharged using gravity through an opening in the base plate.

HD-RC-BH - Chips & Shavings

The HD-RC-BH is a modified HD hog with a more aggressive cut, hardsurfaced ring lugs, and abrasion resistant wear lines in the cutting chamber. This makes it ideally suited for secondary grinding of chips and shavings.

It is typically used for processing chipscreen rejects in pulp mills. Utilizing the Montgomery punch-and-die system, the HD-RC-BH eliminates re-screening and produces a low percentage of pulp fines.

The HD-RC-BH differs from the HD-RC in that it includes an Integral Fan, which conveys the discharge material into a cyclone, truck, or open field.

BS-RC - Chips & Shavings

Designed specifically for secondary grinding, the BS-RC is ideally suited to process the chips and shavings of a pulp and paper mill.

Where chip overs are suspended in slurry, the Bullscreen Rechipper is able to withstand the rigors of a caustic environment. In addition to the aggressive cut and wear liners in the cutting chamber, the bearings are sealed, hose bibs are provided for flushing, stainless steel is welded to the rings, and the housing is covered in a special anti-corrosion epoxy.

PM-HZF-BH - Veneer

The PM-HZF-BH is ideally suited to the heavy-duty processing of veneer. It can accept scrap up to 4" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal feed allows for more efficient grinding of long pieces of veneer, and the Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

PM-HZF-BH - Wood

The PM-HZF-BH is ideal for heavy-duty processing of wood scrap. It can accept blocks, cutoffs, edgings, slabs, and trim ends up to 6” thick.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than the smaller FS or HD models.

The horizontal feed allows for more efficient grinding of long pieces of wood, and the Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

PM-HZF-BH - Particleboard

More powerful than its FS and HD Series counterparts, the PM-HZF-BH makes quick work of particleboard. A rugged machine, it can handle particleboard up to 4" thick, as well as harder materials or even stray nails.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput of large volumes.

The horizontal feed allows for more efficient grinding of long pieces of particleboard, especially when the scrap is over 8 feet long.

An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

PM-HZF-BH - Plywood

The PM-HZF-BH provides a rugged solution to heavy-duty processing of plywood scrap. It can handle scrap up to 4" thick, and the horizontal infeed allows it to accept pieces of plywood over 8 feet long.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than their FS or HD Series counterparts.

An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

PM-HZF-BD - Veneer

The PM-HZF-BD is ideally suited to the heavy-duty processing of veneer. It can accept scrap up to 4" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal feed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long. Material is discharged via gravity through an opening in the base plate of the hog.

PM-HZF-BD - Wood

The PM-HZF-BD is ideal for heavy-duty processing of wood scrap. It can accept blocks, cutoffs, edgings, slabs, and trim ends up to 6” thick.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than the smaller FS or HD models.

The horizontal feed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long. Material is discharged via gravity through an opening in the base plate of the hog.

The 50 PM-HZF BD pictured processes slabs for mulch.

PM-HZF-BD - Particleboard

More powerful than its FS and HD Series counterparts, the PM-HZF-BD makes quick work of particleboard. A rugged machine, it can handle particleboard up to 4" thick, as well as harder materials or even stray nails.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput of large volumes.

The horizontal feed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long. Material is discharged via gravity through an opening in the base plate of the hog.

PM-HZF-BD - Plywood

The PM-HZF-BD provides a rugged solution to heavy-duty processing of plywood scrap. It can handle scrap up to 4" thick, and the horizontal infeed allows it to accept pieces of plywood over 8 feet long.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than their FS or HD Series counterparts.

Material is discharged via gravity through an opening in the base plate of the hog.

PM-HZF-RD - Veneer

The PM-HZF-RD is ideally suited to the heavy-duty processing of veneer. It can accept scrap up to 4" thick and over 8' long.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

The horizontal feed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

PM-HZF-RD - Wood

The PM-HZF-RD is ideal for heavy-duty processing of wood scrap. It can accept blocks, cutoffs, edgings, slabs, and trim ends up to 6” thick.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than the smaller FS or HD models.

The horizontal feed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

PM-HZF-RD - Particleboard

More powerful than its FS and HD Series counterparts, the PM-HZF-RD makes quick work of particleboard. A rugged machine, it can handle particleboard up to 4" thick, as well as harder materials or even stray nails.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput of large volumes.

The horizontal feed allows for more efficient grinding of long pieces of wood, especially when scrap is over 8 feet long.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

PM-HZF-RD - Plywood

The PM-HZF-RD provides a rugged solution to heavy-duty processing of plywood scrap. It can handle scrap up to 4" thick, and the horizontal infeed allows it to accept pieces of plywood over 8 feet long.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than their FS or HD Series counterparts.

Rear discharge with a rectangular to round transition (included) allows pneumatic pickup of discharge material into an existing blowpipe system.

PM-ER - Bark

The PM-ER excels when it comes to processing high volumes of materials. The large 22" cutting circle allows for more throughput and larger input.

Especially in cases where large chunks of bark are mixed in with other waste material, the PM-ER is able to grind with ease. It can handle scrap up to 6" thick.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The PM-ER has an average bark processing capacity of up to 29 tons per hour.

PM-ER - Chips & Shavings

The PM-ER is a heavy-duty piece of equipment that provides a cost-effective solution to grinding chips or shavings. It is available with an optional overlapping cut, which aids in the grinding of stringy materials.

In the case that chips or shavings are mixed in with larger debris, the PM-ER still maintains its aggressive processing capabilities. It can handle scrap up to 6" thick.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog. In the picture shown, a blowpipe connection in the hog's sub-base picks up the material as it exits and sends it through an existing blowpipe system.

The PM-ER has an average chips and shavings processing capacity of up to 14 tons per hour.

The pictured 66 PM-ER is used to process planer mill waste, chips, shavings, & wood blocks.

PM-ER - Gypsum

The PM-ER provides infeed opening options large enough to accommodate sheets of gypsum board.

Able to grind much stronger materials, the PM-ER can process gypsum with ease. It provides a cost-effective way to grind gypsum, while still maintaining an aggressive cut.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The PM-ER has an average gypsum processing capacity of up to 22 tons per hour.

PM-ER - Plastics & Polymers

The PM-ER is tough enough to handle more than just wood. It readily aids in the processing and reducing of many specialty materials such as plastics, polybutadiene blocks, and polyurethane scraps.

A rugged machine, the PM-ER is able to accept scrap up to 6" thick.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

PM-ER - Veneer

When it comes to light materials like veneer, the PM-ER provides a high-volume, heavy-duty option. A rugged machine, it can accept scrap up to 6" thick. A large 22" cutting circle allows for more throughput than its FS or HD Series counterparts.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The PM-ER has an average veneer processing capacity of up to 10 tons per hour.

The 50 PM-ER pictured processes eucalyptus cutoffs and dry veneer scrap.

PM-ER - Wood

The PM-ER is ideal for heavy-duty processing of wood scrap. It can accept blocks, cutoffs, edgings, slabs, and trim ends up to 6” thick.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than the smaller FS or HD models.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The PM-ER has an average wood processing capacity of up to 12 tons per hour.

The 50 PM-ER pictured processes planer mill waste and wood blocks.

PM-ER - Particleboard

Since particleboard is relatively easy to break down, the PM-ER provides an energy-efficient solution to processing scrap. Ideal for heavy-duty applications, it can handle particleboard up to 6" thick, as well as harder materials or even light tramp metal.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The PM-ER has an average particleboard processing capacity of up to 28 tons per hour.

PM-ER - Plywood

A rugged machine designed for high volumes, the PM-ER processes plywood scrap with ease. Able to handle scrap up to 6" thick, it is ideally suited to applications where plywood may be mixed in with larger chunks of wood. It even can process light tramp metal or small nails.

Material is fed into the PM-ER through the top of the machine. Discharge material exits via gravity through an opening in the base plate of the hog.

The PM-ER has an average plywood processing capacity of up to 21 tons per hour.

PM-BH - Bark

The PM-BH excels when it comes to processing high volumes of materials. The large 22" cutting circle allows for more throughput and larger input.

Especially in cases where large chunks of bark are mixed in with other waste material, the PM-BH is able to grind with ease. It can handle scrap up to 6" thick.

Material is fed into the PM-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

The pictured 34PM40 is used to grind cypress bark and wood scrap.

PM-BH - Chips & Shavings

The PM-BH is a heavy-duty piece of equipment that provides a cost-effective solution to grinding chips or shavings. It is available with an optional overlapping cut, which aids in the grinding of stringy materials.

In the case that chips or shavings are mixed in with larger debris, the PM-BH still maintains its aggressive processing capabilities. It can handle scrap up to 6" thick.

Material is fed into the PM-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

The 18PM40 pictured processes hardwood bark, wood scraps, and chips.

PM-BH - Plastics & Polymers

The PM-BH is tough enough to handle more than just wood. It readily aids in the processing and reducing of many specialty materials such as plastics, polybutadiene blocks, and polyurethane scraps.

A rugged machine, the PM-BH is able to accept scrap up to 6" thick.

Material is fed into the PM-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

PM-BH - Veneer

When it comes to light materials like veneer, the PM-BH provides a high-volume, heavy-duty option. A rugged machine, it can accept scrap up to 6" thick. A large 22" cutting circle allows for more throughput than its FS or HD Series counterparts.

The overlapping cut option available for all Montgomery punch-and-die models makes grinding of stringy, spongy, or soft materials like veneer a breeze.

Material is fed into the PM-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

The 50PM40 pictured processes veneer and cores for fuel.

PM-BH - Wood

The PM-BH is ideal for heavy-duty processing of wood scrap. It can accept blocks, cutoffs, edgings, slabs, and trim ends up to 6” thick.

All PM Series hogs utilize a large 22" cutting circle, allowing for more throughput than the smaller FS or HD models.

Material is fed into the PM-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

The 42PM40 pictured is used to process hardwood slabs for mulch.

PM-BH - Particleboard

Since particleboard is relatively easy to break down, the PM-BH provides an energy-efficient solution to processing scrap. Ideal for heavy-duty applications, it can handle particleboard up to 6" thick, as well as harder materials or even light tramp metal.

Material is fed into the PM-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

PM-BH - Plywood

A rugged machine designed for high volumes, the PM-BH processes plywood scrap with ease. Able to handle scrap up to 6" thick, it is ideally suited to applications where plywood may be mixed in with larger chunks of wood. It even can process light tramp metal or small nails.

Material is fed into the PM-BH through a hole in the top of the machine via gravity. An Integral Fan conveniently conveys discharge material up to 100 feet, whether it be into a cyclone, truck, or open field.

HH - Bark

Where stringy bark is not an issue, the HH Series Swinghammer Hog provides a simple, rugged solution. Its spiral design allows for processing of high volumes using less horsepower.

The use of a three-section interchangeable screen allows the HH to endure the pummeling of coarse material while also providing a cost-effective solution to wear.

HH - Gypsum

The HH Series Swinghammer Hog excels in the coarse reduction of solids such as gypsum. Its spiral rotor design assures a constant impacting of the material being processed, so high volumes can be ground while using less horsepower.

HH - Particleboard

When it comes to the coarse reduction of solids such as particleboard, the HH Series Swinghammer Hog shines. It features a spiral rotor design and a unique hammer-locking device, which both aid in reducing the load on the motor.

The HH is a simple yet rugged solution that achieves high processing rates with a lower horsepower requirement.