The Feed Hopper should be a simple means to an end. Straightforward in concept but the wrong geometry can create big headaches. Montgomery Hoppers are thoughtfully designed for both machine and material geometry. When material is fed properly, the abilities of the machine are unleashed.

All gravity-fed models require a Feed Hopper for the safe feeding of material into the hog.

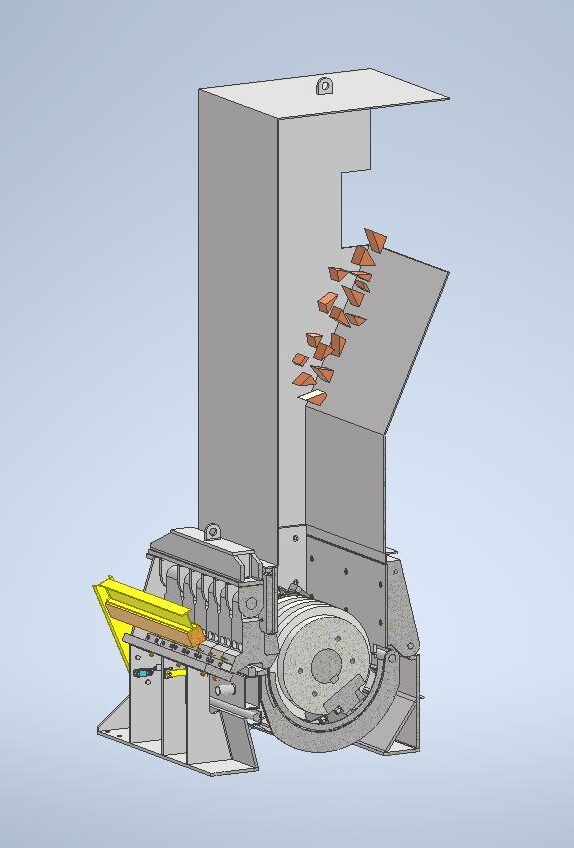

Click on the different Feed Hopper components on the image to the right to learn more about what makes a Montgomery Industries Feed Hopper unique. Or, browse through examples in the slideshow below.

Feed Hopper Components

Hog

A 39 CS-KC Hog with a 30″ Feed Opening is shown for reference. The hopper gets welded onto the hog’s companion flange that then bolts down to the rest of the hog housing.

If you made your own hopper but are finding it doesn’t quite work, not to worry – hogs can easily be retrofitted to include a Montgomery Industries feed hopper.

Infeed Material

The hopper is designed to direct infeed material into the rotor downstroke. This helps prevent kickback and lessens recirculation.

Feed Hopper

The Montgomery Industries Feed Hopper has been carefully engineered with the right geometry for proper feeding of your hog.

Our feed hoppers ensure that material gets directed into the rotor downstroke – not into the walls or ceiling of the hopper.